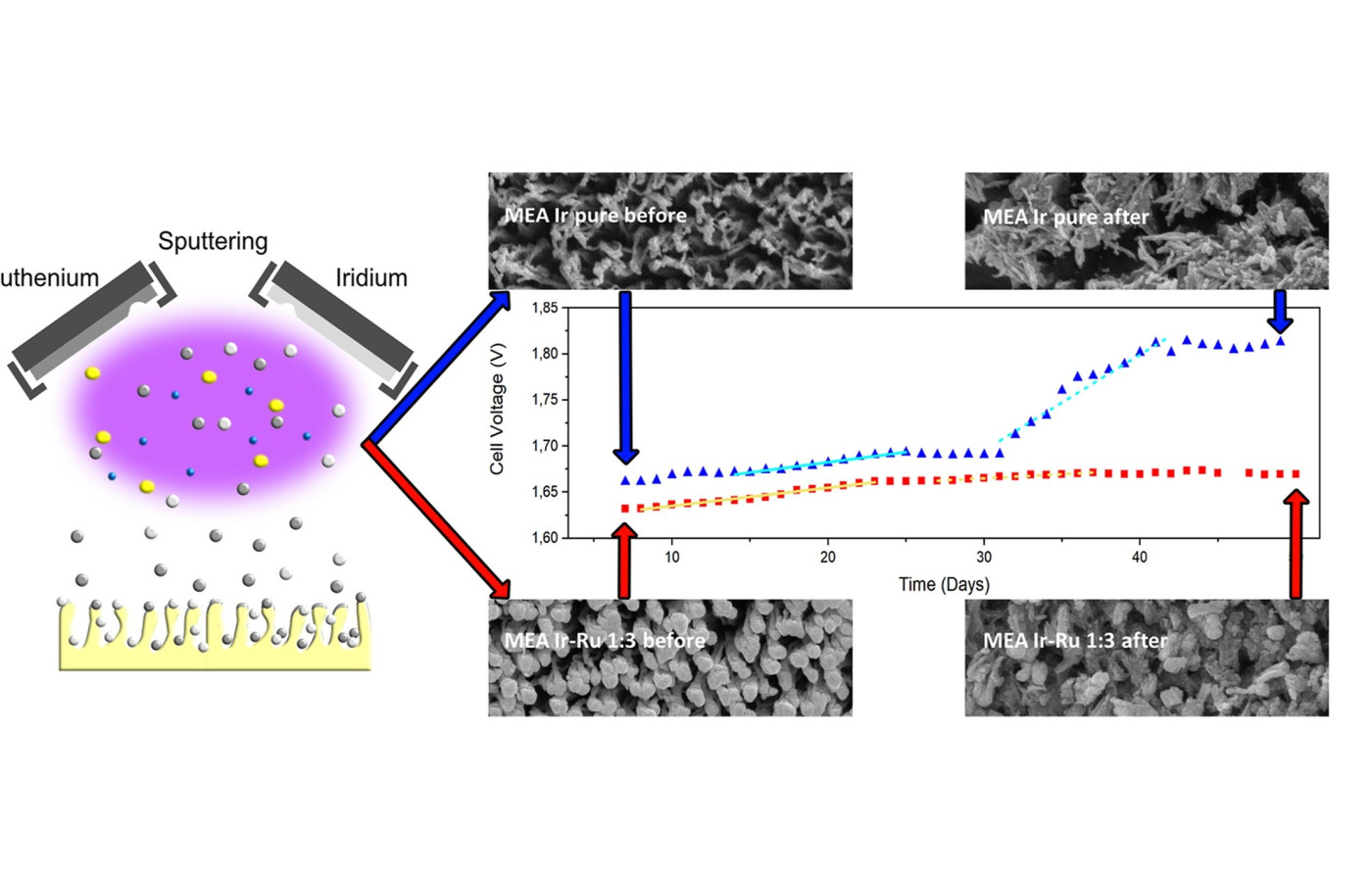

Proton Exchange Membrane Water Electrolyzers (PEM-WEs) are entering the phase of commercial mass production. However, the issue of an iridium catalyst for the anode remains. This work presents an iridium-ruthenium-based catalyst (25% Ir = 158 μg cm−2, 75% Ru) prepared as a thin film on the surface-enhanced-anode of PEM-WE via magnetron sputtering. Using a strictly practical single-cell approach, we show its excellent activity – 1 A cm−2 at 1.606 V, 80 °C, and stability – 1.3 μV h−1 at 1 A cm−2 over the period of 500 h. Together with a purely Ir-based catalyst (158 μg cm−2), we subject it to a massive electrochemical and material analysis, showing that the thickness and interconnectivity are essential for the catalyst's stability. Consequently, we believe that magnetron sputtering is currently the most perspective method for preparing low-Ir-loading catalysts. Compared to the nanoparticle approach, it allows the creation of very thin films with unprecedented interconnectivity.

More information can be found here: https://doi.org/10.1016/j.jpowsour.2022.232375.

© 2021 Matematicko-fyzikální fakulta Univerzity Karlovy.

Všechna práva vyhrazena. | Cookies